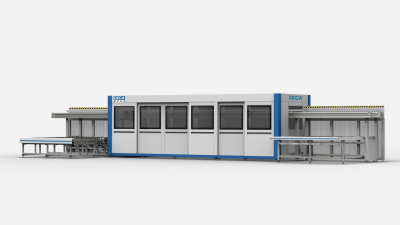

Screwing Machine CNC for PVC Profile ASD-CNC-100E

Features:

Single mode or dual mode process; Left and right clamping on both sides; Loading in cycle to improve efficiency and save time.

Adopt CNC system control, 2-axis servo driver and close-loop control for high precision.

Horizontal moving speed could reach 500mm/s. Running speed is high.

Multi pieces could be clamped at one time. 6 pcs of 60 series profile could be clamped at one time maximumly. Working efficiency is high.

Missing screw detection device; auto screw feeder and unique screw box design is to avoid the block of screw.

Adopt world-known brands of electrical parts: Omron PLC and HMI, Siemens servo system for super good stability.

HMI is friendly for convenient adjustment of parameters.

It is a nice option of big window and door factory.

Function:

This machine is mainly used for automatic fastening the screws between PVC profile and reinforcement steel.

Parameter:

Air Pressure:0.6~0.8(MPa)

Air Consumption:100(L/min)

Input Voltage:220V 50Hz

Input Power: 1.5(kW)

Max. Processing Height: 120mm

Screw Length: 13~45mm ( The minimum length =1.5 times of screw head)

Screw Head Diameter: 6~9mm(selected types of screw head)

Feeding Speed: 30~80 screws per minute

Max. moving distance forward and back: 420mm

Processing Profile Length: Dual mode: 2500mm

Single mode: 5000mm

Overall Dimension:6100×1700×1600(mm)

Weight:900(kg)