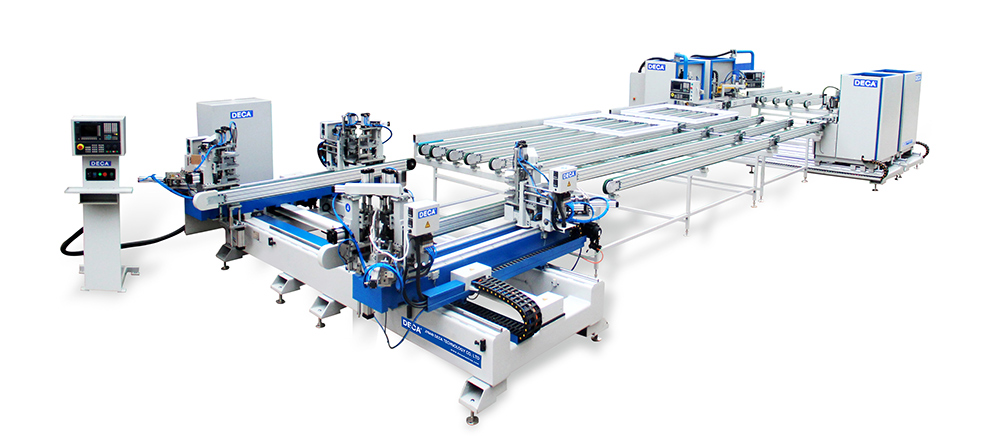

Automatic Welding/Cleaning Production Line

Features:

1.Composed of welding unit, automatic conveying unit and Four head automatic cleaning unit.

2.Horizontal structure with strengthened rigidity design for stable operation.

3.Feeding system of welding head adopts motion square guide rail for good stability and reliability.

4.Unique forced synchronization technology with proprietary technology which increases the strength and qualityof the welding corners.

5.Welding block can be changed very fast and conveniently.

6.Automatic discharging system for double-layer welding to keep machine working more stably and reliably.

7.The Four Head Corner Cleaning Machine can finish the positioning, cleaning and transferring the welded-frames automatically, and no need manual intervention.

Function:

One time finish two rectangle welded frame/sash and corner cleaning automatically.

Features:

1.Composed of welding unit, automatic conveying unit and Four head automatic cleaning unit.

2.Horizontal structure with strengthened rigidity design for stable operation.

3.Feeding system of welding head adopts motion square guide rail for good stability and reliability.

4.Unique forced synchronization technology with proprietary technology which increases the strength and qualityof the welding corners.

5.Welding block can be changed very fast and conveniently.

6.Automatic discharging system for double-layer welding to keep machine working more stably and reliably.

7.The Four Head Corner Cleaning Machine can finish the positioning, cleaning and transferring the welded-frames automatically, and no need manual intervention.

8.The corner cleaning unit can clean welding seam of up/bottom surface, external vertical section and gasket groove with the perfect cleaning effect.

9.Most of the main parts (CNC system, electrical system, pneumatic system etc.)adopt the well-known brand product, more reliable with longer service life.

10.Optimized program design for higher production efficiency.

11.Only need one operator, save labor cost.

12.Especially suit for the factories who produce high-grade PVC Windows & Doors with the large output.

Parameter:

Input Voltage:380V 50Hz

Input Power:32.5kW

Air Pressure:0.5~0.8MPa

Air Consumption:260L/min

Welding Profile Height:30~120mm

Welding Profile Width:≤110mm

Welding Size Range:500mmx650mm~1800mmx3000mm

Cleaning Size range:550mmx750mm~1800mmx3000mm

Overall Dimensions:15500mmx5250mmx2000mm

Weight:6000kg