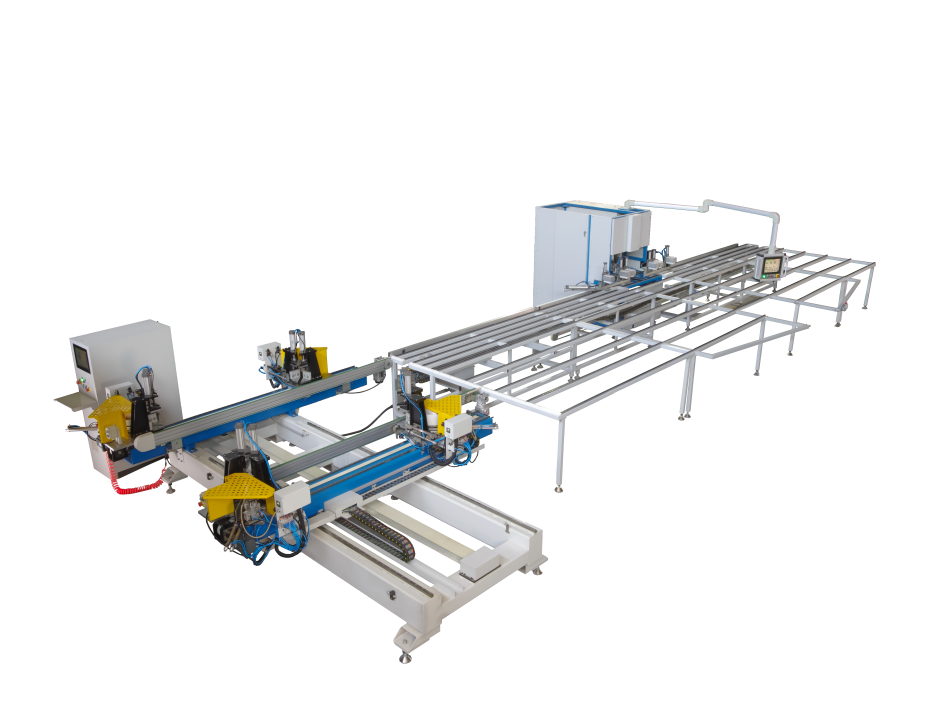

Fully Automatic Welding-Cleaning Line for PVC window and door AWCL-1000

Features:

1.Composed of welding unit, automatic conveying unit and corner cleaning unit.

2.The whole machine adopts motion square guide, linear bearing motion pair for high precision.

3.The whole machine adopts whole set imported brand servo system, industrial computer control for high stability.

4.The bar code reader is optional for reading the label of item and getting the processing data.

5.Program for welding-transferring-cleaning could be optimized for high efficiency.

6.This auto line could meet the requirements for mass production and higher enterprise image.

Function:

Adopt German Stuertz technology. This machine is used for fabricating European Standard high-grade window and door to realize the automatic welding, transferring and corner cleaning.

Features:

1.Composed of welding unit, automatic conveying unit and corner cleaning unit.

2.The whole machine adopts motion square guide, linear bearing motion pair for high precision.

3.The whole machine adopts whole set imported brand servo system, industrial computer control for high stability.

4.The bar code reader is optional for reading the label of item and getting the processing data.

5.Program for welding-transferring-cleaning could be optimized for high efficiency.

6.This auto line could meet the requirements for mass production and higher enterprise image.

Features for welding unit:

1.Machine body with horizontal layout adopts reinforced rigidity design for good stability and reliability.

2.Unique structure for one unit of locating plate and heating plate; Adopts square rail motion pair . It is compact, stable and reliable.

3.Machine heads adopt structure with double timing belt for high locating precision.

4.Can realize welding size auto compensation. Precision for welded product is high.

5.Adopt quick-change welding fixture for higher efficiency.

6.Specific discharging structure can realize auto discharging.

7.According to the customer’s request, machine could be made for single stack frame welding or double-stack sash welding.

8.After welding, the product is transferred in sequence.

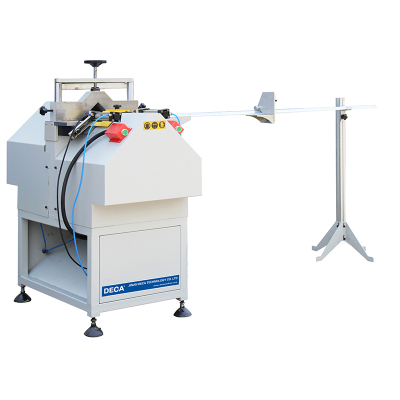

Features for Cleaning Unit:

1.Equipped with high-efficiency servo system and machine with 11 cleaning tools, can realize the quick cleaning for almost all the section of PVC window and door.

2.The unique turning-in-place and inner positioning structure of the cleaning unit can increase the efficiency of whole machine as well as the accurate positioning of the welded item.

3.Installation structure of the cleaning tools adopts upside-down-mounting way for air cylinder for good rigidity.

4.The tool designed with high speed steel and linear bearing motion pair, cleaning result could reach European standard for PVC window and door.

5.Can automatically select processing program.

6.Can realize arc and linear interpolation to get good cleaning result.

Features for transferring device and manipulator:

1.The transferring unit can transfer the welded frame or sash automatically after welding process.

2.Adopts advanced double manipulator design, and servo drive control, square rail motion pair for high efficiency.

3.Unique design for manipulator holding, can automatically realize accurate holding and fast transferring the welded item. Efficiency is high.

Technical Data:

Air Pressure: 0.5~0.8MPa

Air Consumption: 300L/min

Voltage: 380V 50Hz

Input Power: 15kW

Processing Profile Height: 30mm~130mm

Processing Profile Width: 30mm~120mm

Processing range: 400mm×550mm~2500mm×3000mm

Overall Dimension: 14500mm×5000mm×2000mm

Weight: 5000kg